Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

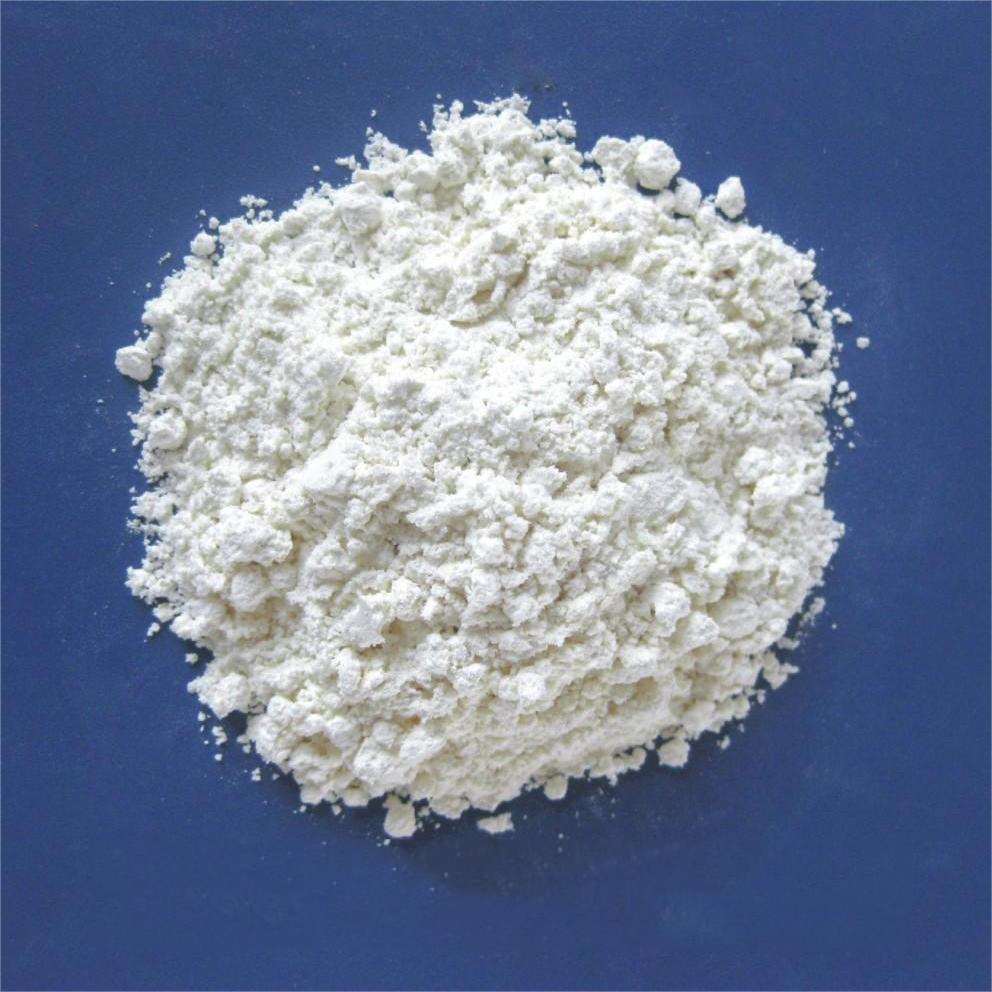

1. Reaction with vulcanizing agents to form active species: rubber accelerators usually react with vulcanizing agents to form active thiol species. These reactive species can react with the double bonds in the rubber molecule to form a cross-linked structure. Through the synergistic effect with vulcanizing agents, rubber accelerators can accelerate the vulcanization reaction of rubber and increase the cross-linking density of rubber, thus improving the strength and toughness of Rubber Products.

3. Improve the fluidity of rubber: rubber accelerator can improve the fluidity of rubber, so that the rubber in the processing process is easier to flow and fill the mold. Rubber needs to go through extrusion, calendering, injection molding and other steps in the process, and fluidity is the key factor to ensure that the rubber is evenly distributed in the process and fill the mold. By adjusting the viscosity and hardness of rubber, rubber accelerators make rubber have better fluidity and can better adapt to different processing requirements.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.